Application of wear-resistant coatings

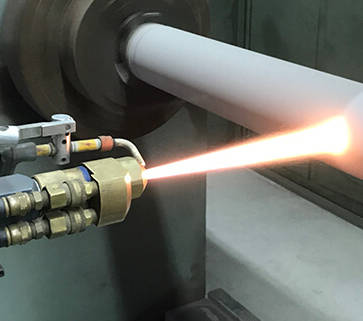

HVOF method

Get wear-resistant coatings for your mechanical parts

Zobacz ofertę

Trust the professionals

Quality guaranteed by certificates

Our company, located in Brzeg in the Opole region, has been in business since 2007 and specialises in the application of abrasion-resistant coatings to mechanical parts.

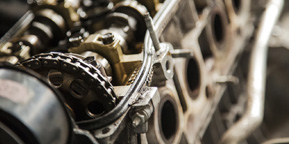

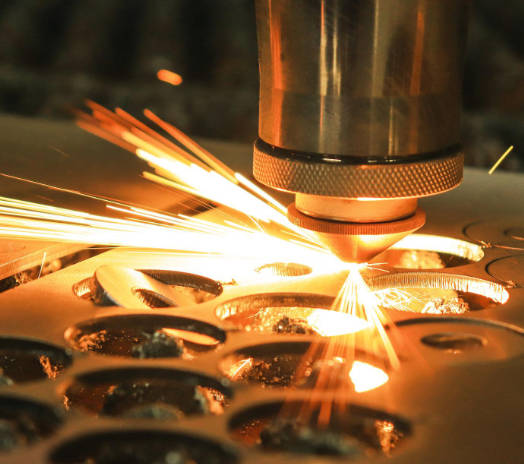

We offer our customers the spraying of both new parts and the reconditioning of worn parts, using certified carbide, steel and ceramic coatings. Depending on the type of component to be sprayed and its working environment, we can offer HVOF, wire and flame spraying.

WięcejUse of coatings

Typical applications of HVOF sprayed coatings

Supersonically sprayed coatings are characterised by low porosity, which increases their resistance to abrasive wear and corrosion, and their properties are readily used in many industries.

OUR OFFER

Application of wear-resistant coatings to mechanical parts by methods: HVOF, wire, flame method.

Taking care of a wide range of services, we can, among other things, offer coatings:

WięcejPROFESSIONAL PROTECTIVE COATINGS

What you gain

HVOF coating formation improves the performance of coatings

It is worth mentioning that the use of the HVOF method is an excellent alternative to technical chromium coatings due to its high resistance to abrasive wear. The HVOF method also allows ground surfaces to be sprayed, which is of great importance for the finishing process.

Increase durability

The quality of machine and equipment parts is of crucial importance for technological processes. With our protective coatings, you will improve the performance and durability of machine and equipment parts.

You will reduce costs

By using our protective coatings, you will reduce the costs associated with their operation and maintenance. In addition, the coatings will extend the life of the equipment by protecting it from the elements.

You will reduce the risks

Reducing the risk of emergency stoppages and interruptions is a difficult goal to achieve. We know how to help you achieve it. Using HVOF protective coatings, will improve the quality of your products and increase your competitiveness.

Dane kontaktowe

Adres

- HVOF-Technika Sp. z o.o.

- ul. Składowa 8

- 49-300 Brzeg

- NIP: 872-22-84-324

Adres e-mail

Telefon

Biuro:

+48 576 209 807Sprzedaż:

+48 601 938 195