- extended service life of mechanical components, and thus less frequent machine downtime

- protection against abrasive wear

- corrosion protection

- thermal barrier

- Increased or reduced coefficient of friction

- reduction of the company's own costs

- ecological aspect - the re-use of the coated part saves resources and energy needed for the production of a new part.

About Us

About Us

What do we do?

Our company is located in Brzeg in the Opole region, has been in business since 2007 and specialises in the application of wear-resistant coatings to mechanical parts. We offer our customers spraying of both new parts and regeneration of worn parts, using certified carbide, steel and ceramic coatings. Depending on the part to be sprayed and its working environment, we can offer HVOF, wire and flame spraying.

What you gain

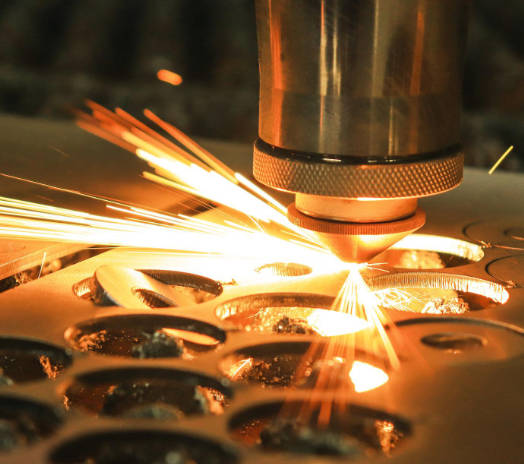

HVOF coating formation improves the performance of coatings

Increase durability

The quality of machine and equipment parts is of crucial importance for technological processes. With our protective coatings, you will improve the performance and durability of machine and equipment parts.

Reduce costs

By using our protective coatings, you will reduce the costs associated with their operation and maintenance. In addition, the coatings will extend the life of the equipment by protecting it from the elements.

Reduce the risks

Reducing the risk of emergency stoppages and interruptions is a difficult goal to achieve. We know how to help you achieve it. Using HVOF protective coatings, will improve the quality of your products and increase your competitiveness.